Application

The Uhing Measuring System detects the position of flanges on spools, regardless of the spool used. After a spool change, the system automatically adjusts to the new spool position and, where necessary, the new spool shape.

The Uhing Measuring System was specially designed for application with pneumatically reversible rolling ring drives but can also be fitted on other traversing systems after testing.

Your Advantage

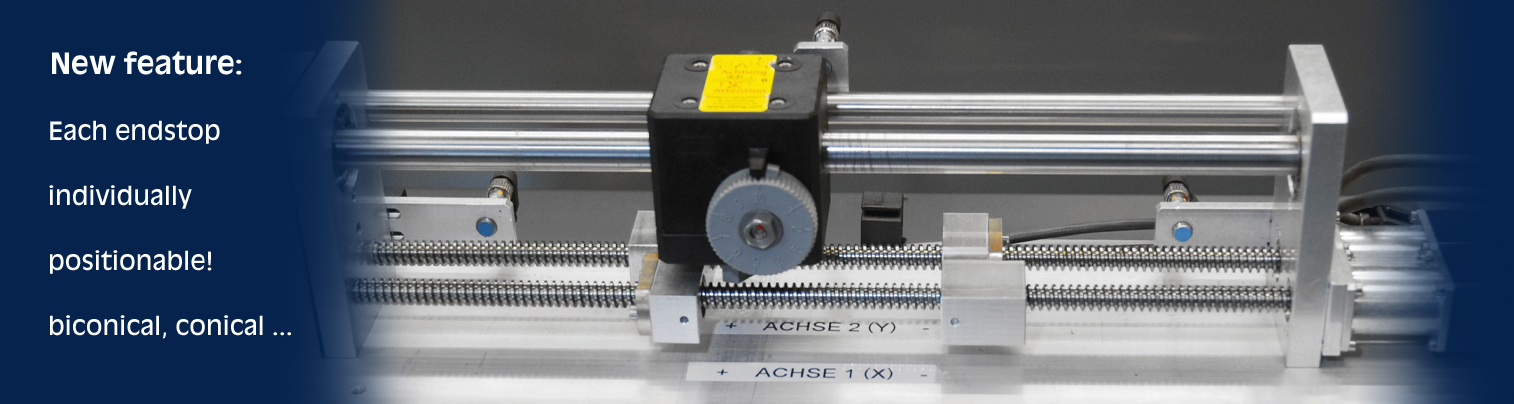

• No manual adjustment of reversal points

• Significant time savings when spools of

different type and dimension are used, because adjustment is not required

• Very easy operation

• No prior experience required

• Perfect winding patterns

• No machine data required from customer

• Robust sensor technology

• Modular system

Principle of function

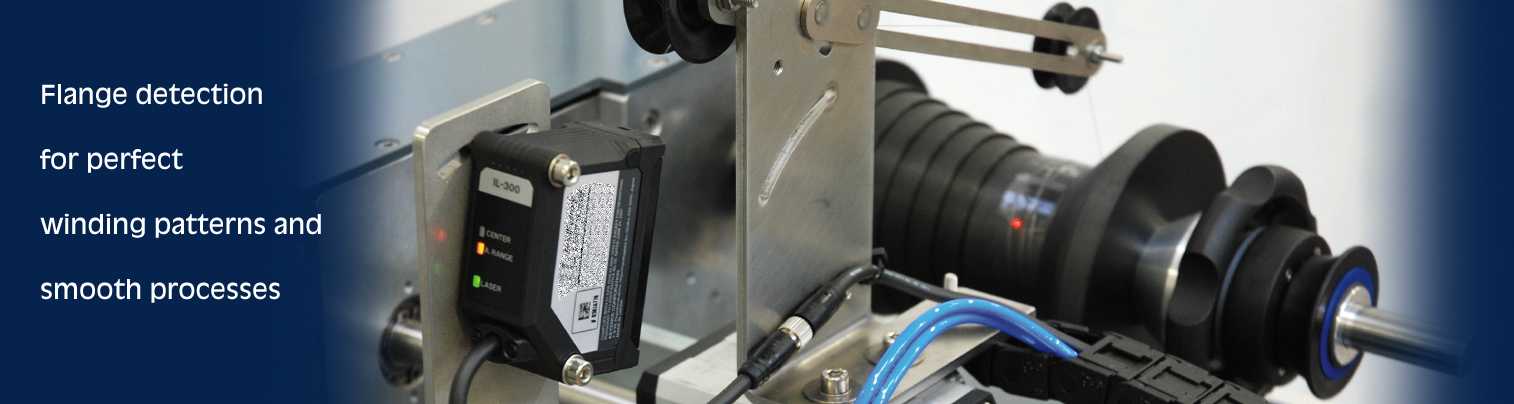

The sensor detecting the flange is mounted on the traversing system.

At a defined point, the current distance is captured and saved as reference distance for each single layer.

While the traversing system moves, the reference distance is continuously compared to the measured value. A reversal is triggered as soon as the permissible, adjustable height deviation is exceeded. Such a height deviation occurs when the flange or an accumulation of material on the spool is detected.

A display indicates either the measured height or the permissible height deviation.

Areas of application

The system has been designed for laying round material with diameters of 0.1 to 2.0 mm on cylindrical spools. Other dimensions are possible after consultation. Spools of different sizes can be wound without readjustment. In this context, the diameters of the spool core (dcore) and the flanges (dflange) must be heeded. The difference must not exceed 220 mm (dflange - dcore < 220 mm).

When using several spools, the smallest core diameter and the largest flange diameter applies.

Other spool sizes are possible as variant.

Flanges can be rectangular or conical up to an angle of 40°; the bulging of flanges is compensated for. Scanning of spools with collapsed flanges is not possible.

The traversing system must be mounted parallel to the spool axis. For very slow winding speeds, the axial run-out of the shaft carrying the spool should not be smaller than the smallest diameter of the material to wind.

Have you any questions? Please contact us by email or via phone.

Uhing Measuring System application video

Press releases

Proven in the field: FA II Flange Detecting System

Many companies producing material to be wound are familiar with this situation: Although spools of the same dimensions are used, their individual dimensions are not exactly identical. Minimal size deviations lead to an uneven winding pattern or even tangling. The result: Increased manual adjustment work – a cost item you could do without....[read more]

Non-Contact Flange Detection with Laser Sensors

Uhing launches the next-generation flange detecting system for rolling ring drives.

In 2004, Uhing added the non-contact FA flange detecting system for rolling ring drives to its product range. This economically priced solution that automatically corrects the reversal points of rolling ring traversing gears relieves the employees in production companies of manual adjustment work and thus reduces time requirements and costs. ...[read more]